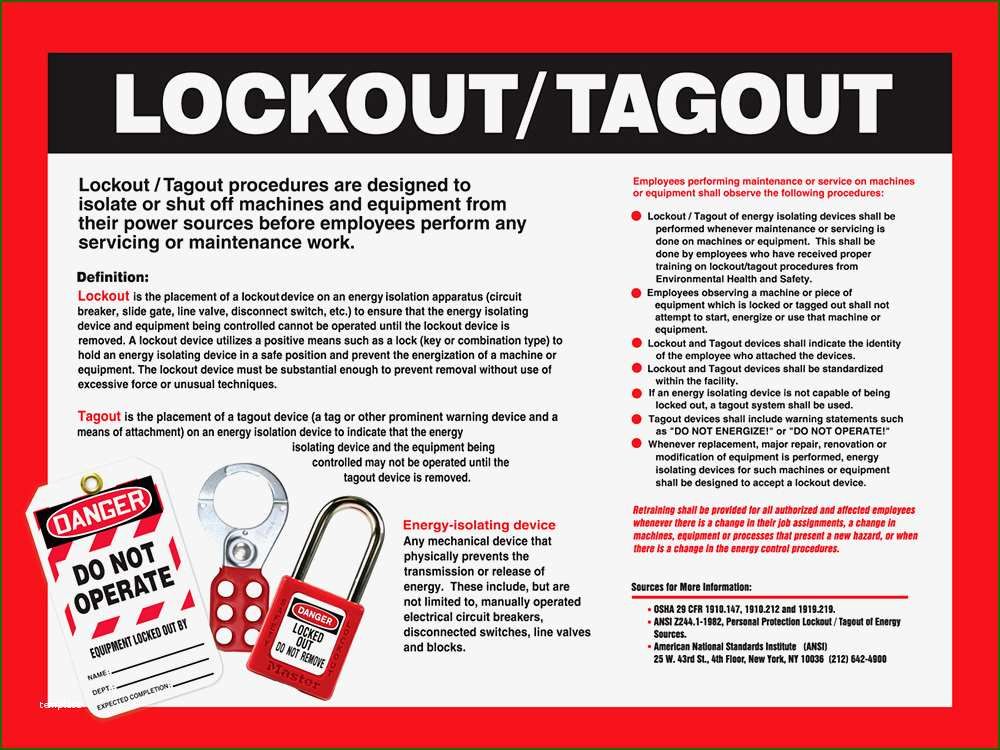

Essential Paperwork for Lockout Procedures: A Comprehensive Guide

In the realm of workplace safety, the meticulous documentation associated with lockout/tagout (LOTO) procedures plays a pivotal role. Whether you are initiating or executing these procedures, understanding the intricacies of the necessary paperwork not only ensures compliance with safety regulations but also facilitates the prevention of accidents. This guide delves into the essential documents required for lockout procedures, elucidating their importance and how they contribute to a safer work environment.

Why Documentation Matters in Lockout/Tagout?

Safety documentation in lockout/tagout isn’t just about compliance; it’s a cornerstone for risk management and effective communication within the workplace. Here are the reasons why:

- Legal Compliance: It is imperative to follow the OSHA standards or your country’s safety regulations, which often mandate detailed documentation.

- Accountability: Records clarify who performed the lockout and when, providing an audit trail for accountability.

- Procedural Clarity: Written procedures ensure that each lockout/tagout action is consistent, reducing the likelihood of errors.

- Safety Training: These documents serve as training materials for new employees or those undergoing refresher courses.

Types of Documentation Required for Lockout Procedures

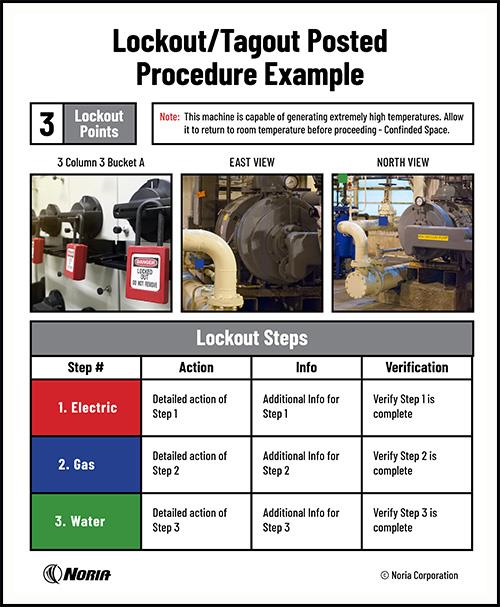

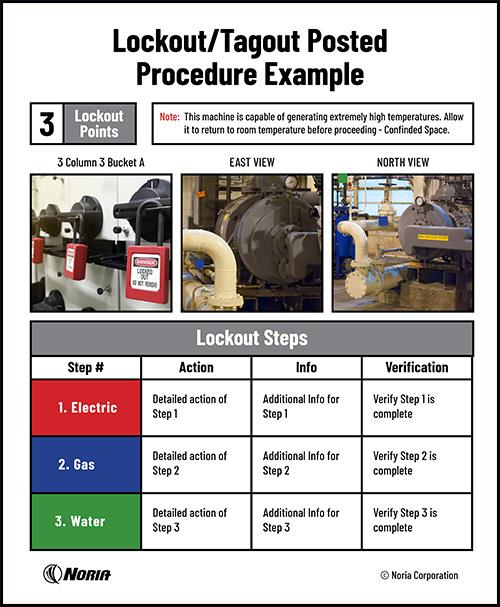

1. Lockout/Tagout Procedure Document

This is the most critical piece of documentation. It outlines:

- Machine or Equipment Identification: Clearly defines which equipment is involved.

- Hazardous Energy Types: Details all energy sources and their control points.

- Energy Isolation Steps: A step-by-step guide on how to isolate and safely lock out energy sources.

- Tagging Procedures: How and where tags should be applied.

- Restoration Steps: Safe procedures to remove the lockout/tagout devices.

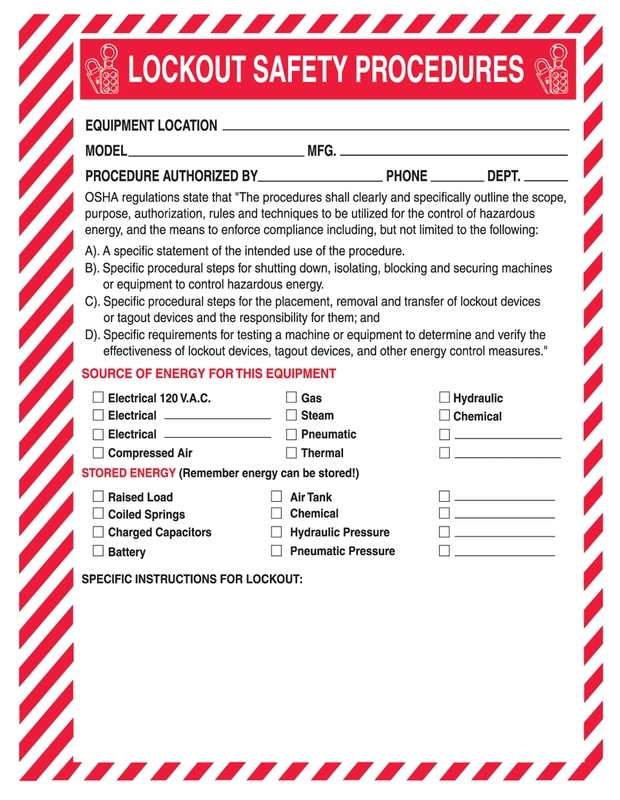

2. Lockout Authorization Form

Before initiating lockout, an authorization form is usually completed to document:

- Date and time of lockout.

- Name and signature of the authorized personnel performing the lockout.

- Details of the equipment being locked out.

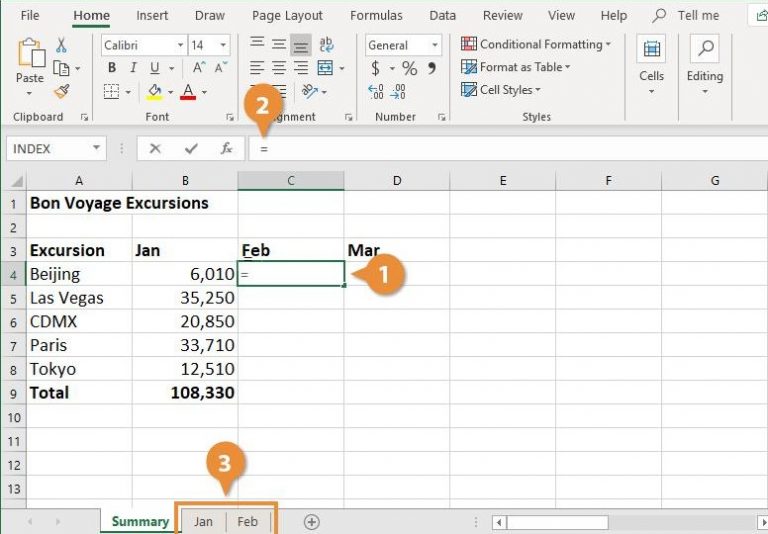

3. Lockout/Tagout Log

A log should be maintained to record:

- The date and time of lockout/tagout.

- Who placed or removed lockout/tagout devices.

- Any anomalies or issues encountered during the lockout process.

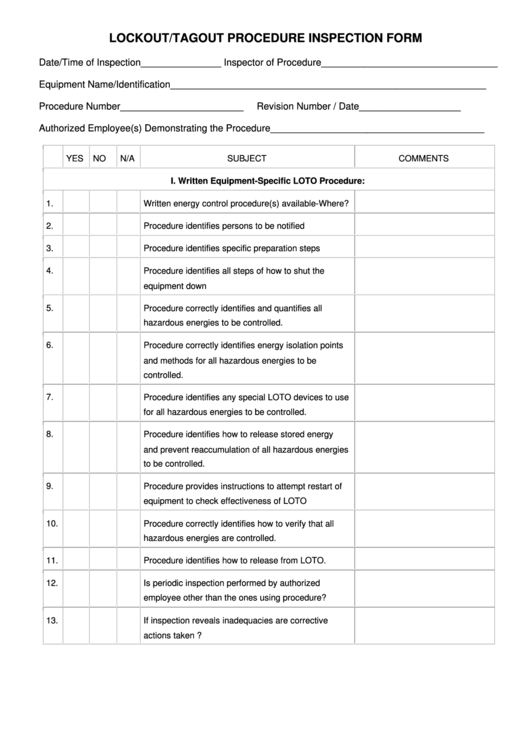

4. Periodic Inspection and Certification

OSHA mandates periodic inspections. This document records:

- The inspector’s identity and date of inspection.

- Whether the procedure was being followed correctly.

- Recommendations for improvement.

5. Employee Training Records

To ensure that all employees are competent in lockout/tagout, training records are crucial:

- Names of trained employees.

- Training dates and duration.

- Outline of what was covered in the training.

🔧 Note: Ensure all documents are legible, easily accessible, and kept up to date to meet compliance requirements and facilitate safe operations.

Implementing Lockout/Tagout Documentation

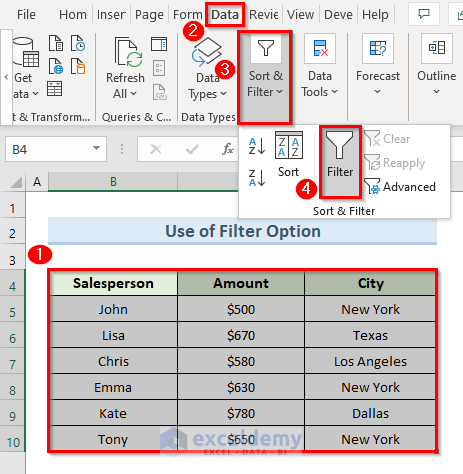

Here’s how you can effectively manage lockout/tagout documentation:

- Standardize Documentation: Develop templates for each document type to maintain consistency.

- Accessibility: Ensure all documents are accessible to those who need them, possibly via digital solutions.

- Regular Updates: Regularly review and update procedures, especially when new equipment is introduced or existing systems are modified.

- Audit Trails: Maintain a clear audit trail for all lockout/tagout activities.

- Communication: Clearly communicate any changes in procedures to all relevant personnel.

🔍 Note: Paperwork alone isn't sufficient; regular training and practical exercises are essential to make the documentation meaningful in real-world scenarios.

The procedural documents and training materials form the backbone of any robust lockout/tagout program. By ensuring these are in place, communicated, and reviewed regularly, organizations can significantly reduce the risks associated with hazardous energy. Proper documentation not only aids in compliance but also fosters a culture of safety, where every step taken is documented and understood, thus minimizing accidents and enhancing overall safety performance. In our final thoughts, we recognize that while paperwork might seem like an administrative burden, it's a critical component of a proactive safety strategy.

What is the purpose of a lockout/tagout procedure document?

+

The lockout/tagout procedure document outlines the specific steps needed to safely isolate energy sources, reduce or eliminate the risk of accidents, and ensure that equipment cannot be operated until it is safe to do so.

How often should lockout/tagout procedures be reviewed and updated?

+

Lockout/tagout procedures should be reviewed and updated annually, or when there are significant changes to the equipment, processes, or regulations that affect safety protocols.

What are the consequences of not following lockout/tagout procedures?

+

Failing to follow proper lockout/tagout procedures can lead to severe injuries or fatalities due to the accidental release of hazardous energy, regulatory fines, and potential legal actions against the organization.