Create Your Own Steel Design Excel Spreadsheet Easily

Designing a steel design Excel spreadsheet from scratch can seem like a daunting task, especially for those who are not deeply familiar with engineering calculations or Excel functionalities. However, with the right tools and a step-by-step approach, you can create an effective tool that not only simplifies your work but also enhances your understanding of steel design principles. This blog post will guide you through the process of creating your own steel design Excel spreadsheet, tailored to your specific needs.

Why Design Your Own Steel Design Excel Spreadsheet?

Before diving into the how-to, it’s worth understanding why you might want to create your own steel design spreadsheet:

- Customization - Your design might have unique parameters or considerations that general-purpose software might not cater to effectively.

- Cost-Effective - Developing your own tool can be cheaper than purchasing commercial software, especially if you’re not requiring extensive features.

- Educational Value - Building your own tool helps deepen your understanding of steel design principles and the underlying calculations.

- Flexibility - You can easily modify your spreadsheet to accommodate changes in design standards or to analyze different scenarios quickly.

Getting Started with Your Excel Steel Design Spreadsheet

Here’s how you can begin crafting your steel design Excel spreadsheet:

1. Define Your Goals and Requirements

Start by determining what exactly your spreadsheet needs to do. Are you focusing on:

- Section property calculations?

- Load analysis?

- Designing steel beams or columns?

- Checking for specific design constraints or standards?

Once you’ve got your objectives clear, you can better plan your spreadsheet layout.

2. Set Up Your Excel Workbook

Create a new workbook in Excel, and label your first sheet something like “Introduction” or “Sheet1”. Here, you can:

- Include basic instructions on how to use the spreadsheet.

- List all the references or design standards you’re considering.

3. Layout Your Spreadsheet

Think about how you want to structure your spreadsheet:

- Input Sheets - For entering material properties, member dimensions, load cases, etc.

- Calculation Sheets - Where all the computations occur.

- Output Sheets - Summarize the design results.

4. Input Sheets

Create sheets for inputting the basic information:

- Steel grade, dimensions of sections, and other material properties.

- Loads - include both gravity and lateral loads.

- Boundary conditions - support conditions, span lengths, etc.

5. Calculation Sheets

Set up sheets where you’ll perform calculations. Here are some key elements:

- Formulas - For calculating section properties like area, moment of inertia, section modulus, etc.

- Stress Checks - To ensure your steel sections are not overstressed under the applied loads.

- Deflection Check - Ensuring the deflections are within acceptable limits.

| Parameter | Description | Formula |

|---|---|---|

| Area (A) | Total cross-sectional area | A = ∑(Ai) |

| Moment of Inertia (I) | Resistance to bending | I = ∑(Ai * yi2) |

| Section Modulus (Z) | Strength of the section | Z = I/ymax |

⚠️ Note: Always use consistent units when inputting values to prevent errors in calculations.

6. Output Sheets

Use these sheets to present results:

- Pass/Fail summaries for design checks.

- Graphs or visual aids for better understanding of results.

Advanced Features to Consider

Once you have the basic structure in place, consider adding some of these advanced features:

- Data Validation - Use data validation rules to ensure correct input values.

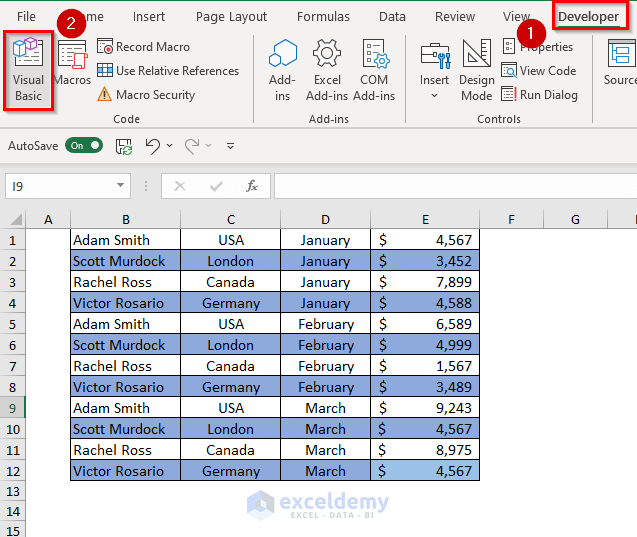

- Macros and VBA - Automate repetitive tasks like copying data between sheets or running complex calculations.

- Error Checking - Implement conditional formatting or formulas to highlight potential errors or non-compliant designs.

🔍 Note: Learning basic VBA can significantly enhance the functionality of your spreadsheet.

Wrapping Up

Creating your own steel design Excel spreadsheet requires a blend of civil engineering knowledge, Excel proficiency, and an eye for detail. By following the steps outlined in this post, you can develop a tool that not only meets your professional needs but also empowers you to perform design checks and analysis with greater efficiency and accuracy. From defining your objectives to implementing advanced features, your journey in steel design calculation can be both educational and practical.

Remember, this tool is not just about reducing manual labor; it's about understanding the principles behind the calculations, customizing solutions for specific projects, and learning through doing. Keep refining your spreadsheet, stay updated with design standards, and share your knowledge with peers for further insights and improvement.

Can I share my Excel design spreadsheet with others?

+

Yes, you can share your Excel design spreadsheet with others. However, ensure that you protect sensitive data or intellectual property before sharing, and make sure that users understand how to use it correctly.

What are the limitations of using an Excel spreadsheet for steel design?

+

Excel spreadsheets can lack the robustness of commercial software for complex designs, might not handle iterative calculations well, and require regular updates to comply with evolving design standards.

How do I ensure my Excel spreadsheet is accurate?

+

To ensure accuracy, always validate your calculations with manual checks or with industry-standard software, update regularly to incorporate changes in design standards, and cross-check your results with peers or third-party reviewers.