Capacitive Production Planning: Excel Sheet Guide

In the world of manufacturing, capacitive production planning plays a critical role in ensuring that resources are used efficiently, and production schedules are aligned with demand forecasts. Excel, being a versatile tool for data analysis and planning, can be leveraged to create a powerful planning system for capacitive production. This guide will walk you through how to set up an Excel sheet for capacitive production planning, highlighting the necessary steps, functions, and considerations to optimize your manufacturing processes.

Why Use Excel for Capacitive Production Planning?

Excel is widely accessible, familiar to most business professionals, and capable of handling complex calculations and data manipulation. Here’s why it’s an excellent choice:

- Flexibility: Easily customize templates and formulas to meet unique production requirements.

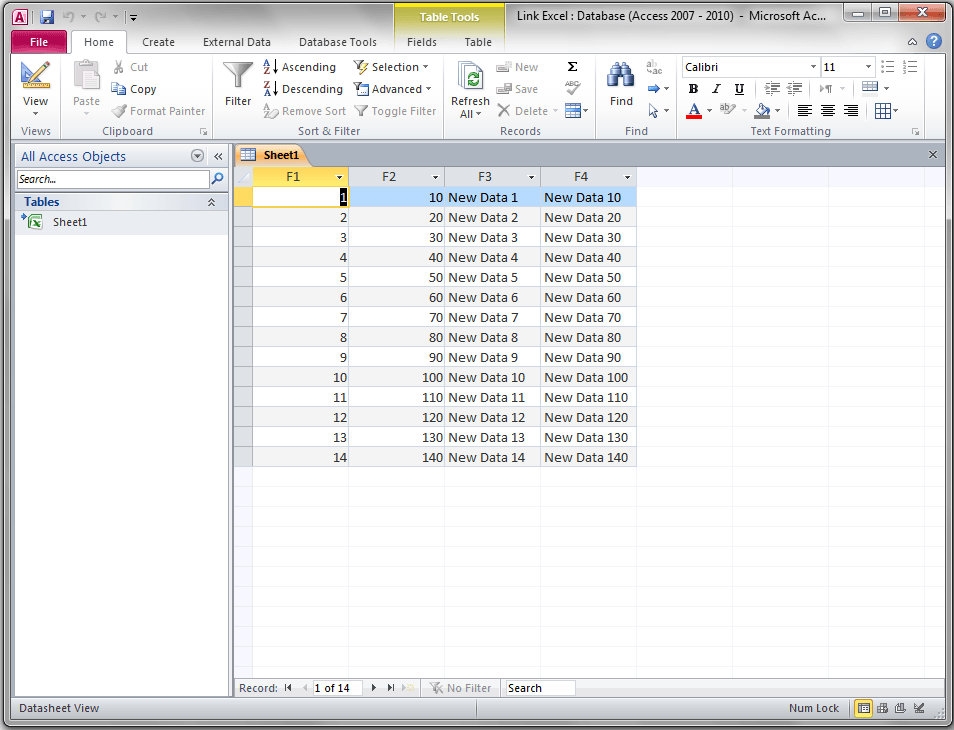

- Data Integration: Connect with various data sources for real-time updates.

- Analysis Capabilities: Utilize Excel’s built-in tools for scenario analysis, forecasting, and more.

Setting Up Your Excel Sheet for Capacitive Production Planning

1. Data Collection and Entry

Begin by collecting all relevant data:

- Product Catalog: List all products manufactured along with their unique identifiers.

- Resource Capacity: Enter capacities for each resource (machines, labor, etc.).

- Production Schedule: Times, shifts, and holidays that affect production capacity.

Here’s how you can organize your data:

| Product ID | Product Name | Machine ID | Units per Hour | Shift Times |

|---|---|---|---|---|

| PR001 | Widget A | M001 | 10 | 08:00-16:00 |

| PR002 | Widget B | M002 | 15 | 16:00-00:00 |

2. Formulas for Capacity Calculation

To calculate production capacity, you’ll need:

- Total Available Time: =NETWORKDAYS(Today(), EndDate, [Holidays]) * Working Hours per Day

- Resource Availability: Adjust for maintenance, downtime, etc.

- Production Rate: Units produced per hour by each resource.

- Capacity: =Total Available Time * Production Rate

3. Demand and Forecast Integration

Integrate your sales forecast into the Excel sheet:

- Use separate columns to enter monthly, weekly, or daily demand forecasts.

- Use formulas like =FORECAST.LINEAR(x,known_y’s,known_x’s) for trend forecasting.

4. Production Scheduling

Allocate production based on capacity and demand:

- Utilize conditional formatting to visually depict overcapacity or underutilization.

- Employ the Solver add-in to find optimal production schedules.

5. Cost Analysis and Optimization

Include cost factors:

- Calculate total production costs based on machine hours, labor, and materials.

- Use Excel’s Goal Seek to minimize costs while meeting production targets.

6. Reporting and Visualization

Create dynamic reports:

- Develop PivotTables to summarize production data.

- Construct charts like Gantt charts to visualize production schedules.

Key Considerations

Here are some considerations to enhance your Excel production planning:

- Data Validation: Ensure data entry accuracy with Excel’s validation rules.

- Backup and Version Control: Regularly save versions to track changes and recover data.

- Security: Protect sensitive information with passwords and lock cells as needed.

📝 Note: Always double-check formulas and data sources for accuracy to prevent miscalculations in planning.

Wrapping Up

In conclusion, Excel offers a robust platform for capacitive production planning. By setting up your Excel sheet with the steps outlined above, you can effectively manage production capacity, align schedules with demand, and analyze costs. Remember, the key to successful production planning lies not just in setting up the sheet but also in regularly updating and refining the data to keep pace with business changes.

Can I use Excel for production planning in large-scale manufacturing?

+

Yes, Excel can be scaled for large manufacturing operations with features like macros, VBA scripting, and integration with other enterprise systems for data management.

How often should I update my production planning Excel sheet?

+

Updates should be at least weekly or more frequently if there are significant changes in demand, supply, or production capacity.

What are the limitations of using Excel for production planning?

+

Excel has limitations in real-time collaboration, handling very large datasets, and complex predictive analytics. It might require integration with other tools for advanced features.

Is there a way to automate some tasks in my Excel production plan?

+

Yes, through VBA (Visual Basic for Applications), you can automate repetitive tasks like data updates, report generation, and even basic decision-making processes.