5 Key Things About Lockout Paperwork You Should Know

Lockout/tagout paperwork is a crucial component of ensuring safety in environments where energy isolation is required for maintenance, servicing, or repair. These protocols, mandated by regulations like OSHA in the United States, are designed to protect workers from the accidental startup of machinery or equipment during maintenance operations. Understanding the key elements of lockout paperwork is essential for any organization involved in such activities. Here are five key things you should know:

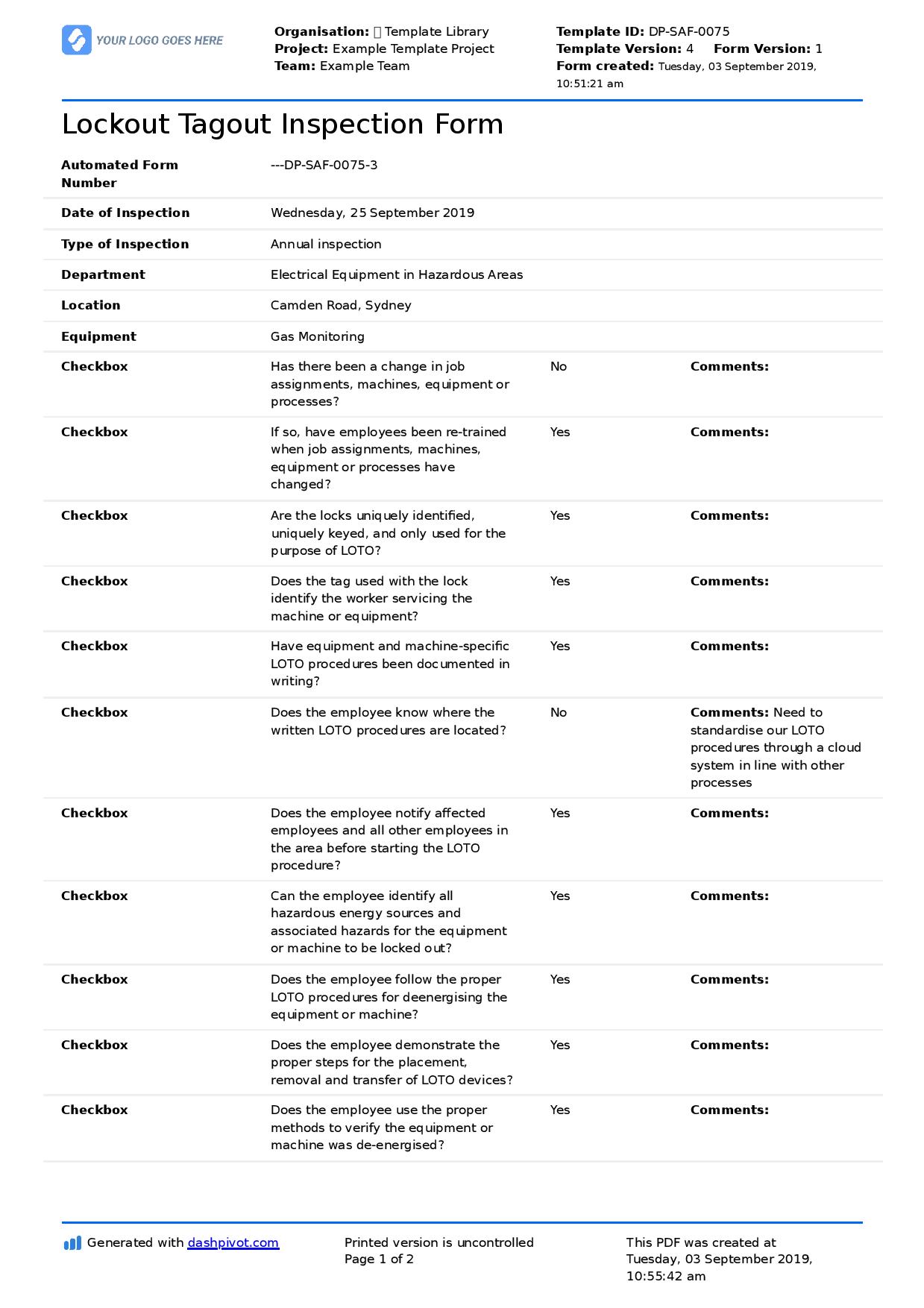

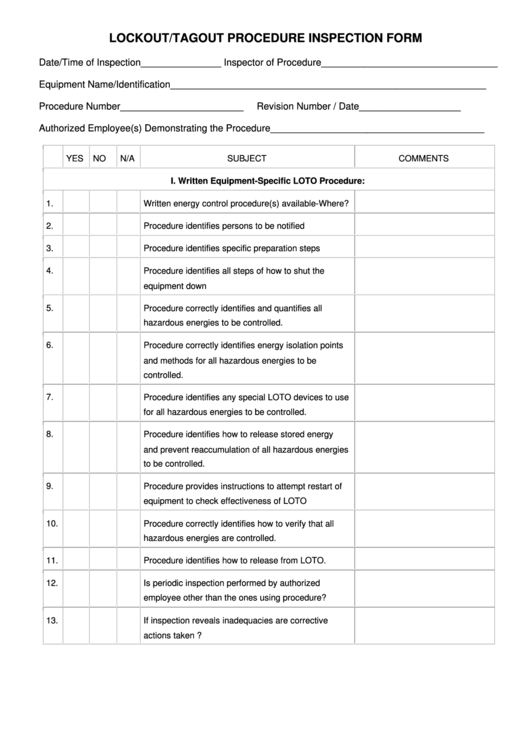

1. Documentation Details

Lockout/tagout documentation isn’t just a formality; it’s a comprehensive record that outlines critical steps and responsibilities:

- Procedure Documentation: A detailed lockout/tagout procedure that specifics the steps for energy isolation, equipment shutdown, application of lockout devices, and safe restoration of operations.

- Employee Authorization: Records of who is authorized to perform lockout/tagout procedures. This includes their training records, ensuring they are competent to handle lockout/tagout operations safely.

- Equipment List: A log or list of all equipment requiring lockout/tagout procedures, often with serial numbers or descriptions for reference.

2. Compliance with Regulations

Ensuring compliance with local, national, or international regulations is vital:

- OSHA Standards: In the USA, adherence to OSHA’s 1910.147 standard for the Control of Hazardous Energy is a must.

- Regular Audits: Conduct periodic internal or third-party audits to confirm adherence to lockout/tagout protocols.

- Documentation Retention: Keep records for at least the duration specified by regulations, which might be several years, depending on the jurisdiction.

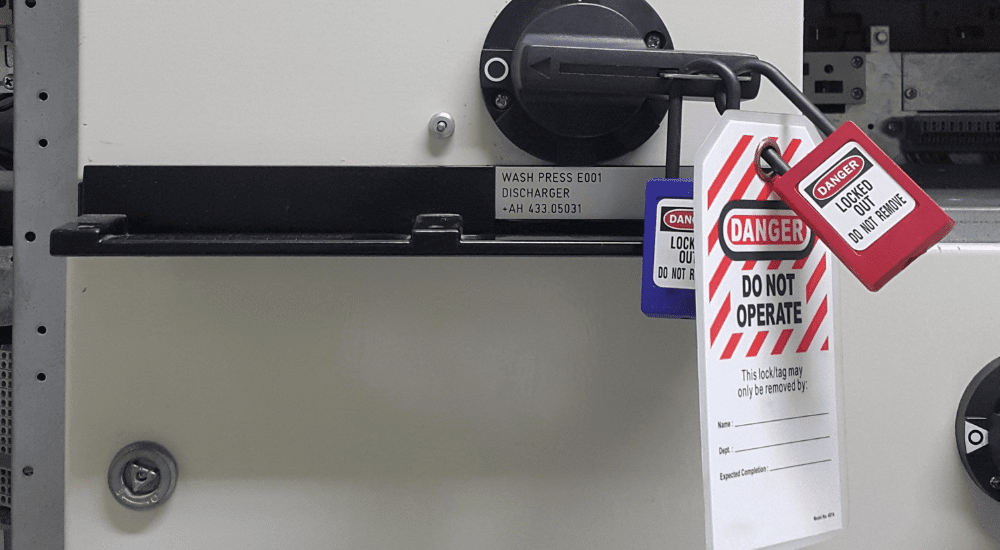

3. Lockout/Tagout Devices and Identification

The actual devices used for lockout and tagout are critical components:

- Tagging: Tags attached to locked-out equipment should clearly identify the person responsible for the lockout.

- Lock Types: Different types of locks are needed for various machines, ensuring that only the person who locked out the equipment can unlock it.

- Device Standards: Locks and tags must meet specific safety standards to ensure they do not fail during the lockout period.

4. Training and Awareness

Thorough training is critical to the effectiveness of lockout/tagout protocols:

- Employee Training: Training should include hazard recognition, the correct application of lockout devices, and the importance of following lockout/tagout procedures.

- Refresher Courses: Regular training sessions to update employees on the latest procedures or changes in regulations.

- Awareness Campaigns: Promote a safety culture where workers are vigilant about lockout/tagout procedures.

5. Ongoing Record-Keeping and Revision

Documentation needs to evolve with changes in equipment, regulations, and company practices:

- Record Updates: Regularly update lockout/tagout records to reflect changes in equipment, personnel, or procedures.

- Revision History: Keep a clear revision history to track changes over time.

- Incident Reporting: If incidents occur, document them to understand any shortcomings in the lockout/tagout process and to make necessary adjustments.

Lockout/tagout paperwork is not merely an administrative task; it is a critical safeguard for worker safety. By ensuring that your lockout/tagout documentation is complete, accurate, and regularly updated, you can protect your workforce from potential hazards, adhere to legal requirements, and uphold the highest safety standards. Remember, the documentation's purpose is to guide workers safely through the process of isolating energy sources and preventing unexpected re-energization of machinery. Always strive for a culture where lockout/tagout procedures are second nature to all employees, thereby reducing accidents and enhancing workplace safety.

What makes lockout/tagout procedures important?

+

Lockout/tagout procedures are crucial for preventing accidents during maintenance or repair work, safeguarding employees from potential harm caused by unexpected energy releases from machinery.

How often should lockout/tagout training be conducted?

+

OSHA recommends annual training for lockout/tagout procedures. Additionally, refresher training should be conducted when there are changes in procedures, equipment, or personnel responsibilities.

What should be done if a worker finds a lockout/tagout device that is not theirs?

+

If a worker encounters a lockout/tagout device not theirs, they should not attempt to unlock or remove it. Instead, they should locate the individual whose name is on the tag or inform the supervisor to proceed with the proper safety measures to ensure it can be safely removed.