HACCP Paperwork Simplified: Go Digital with Ease

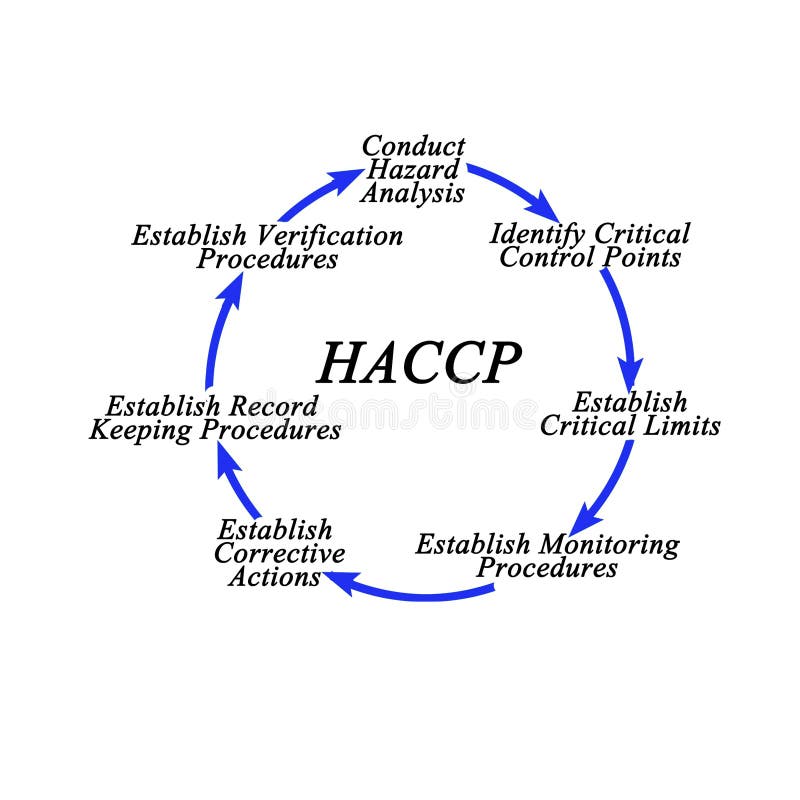

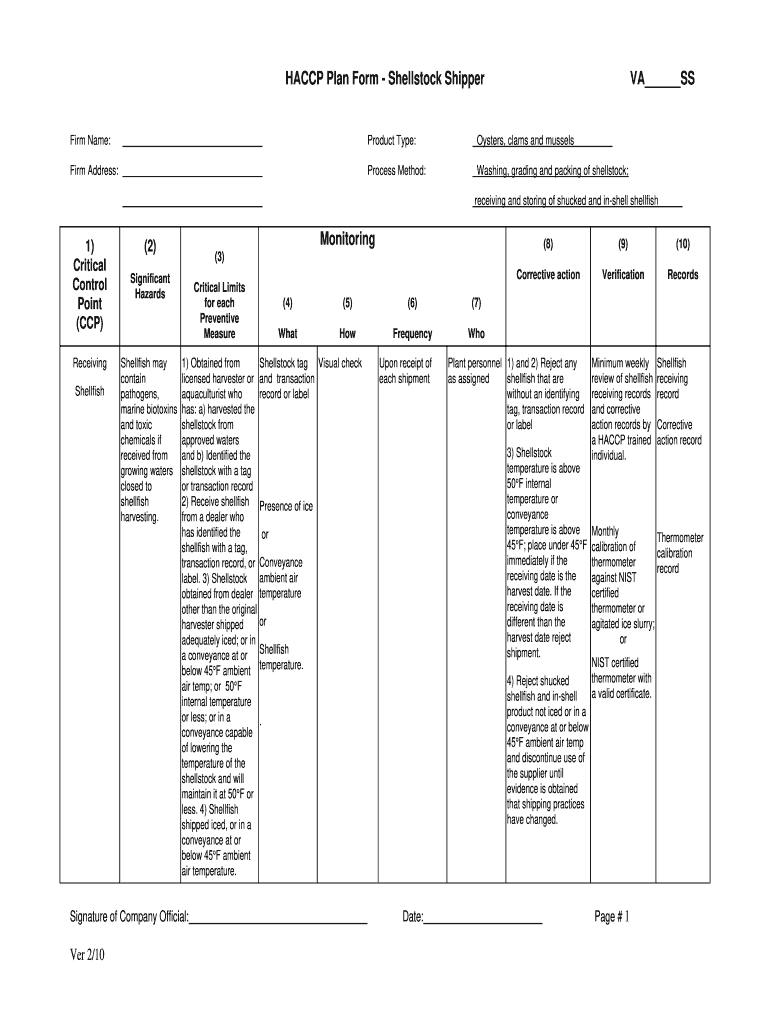

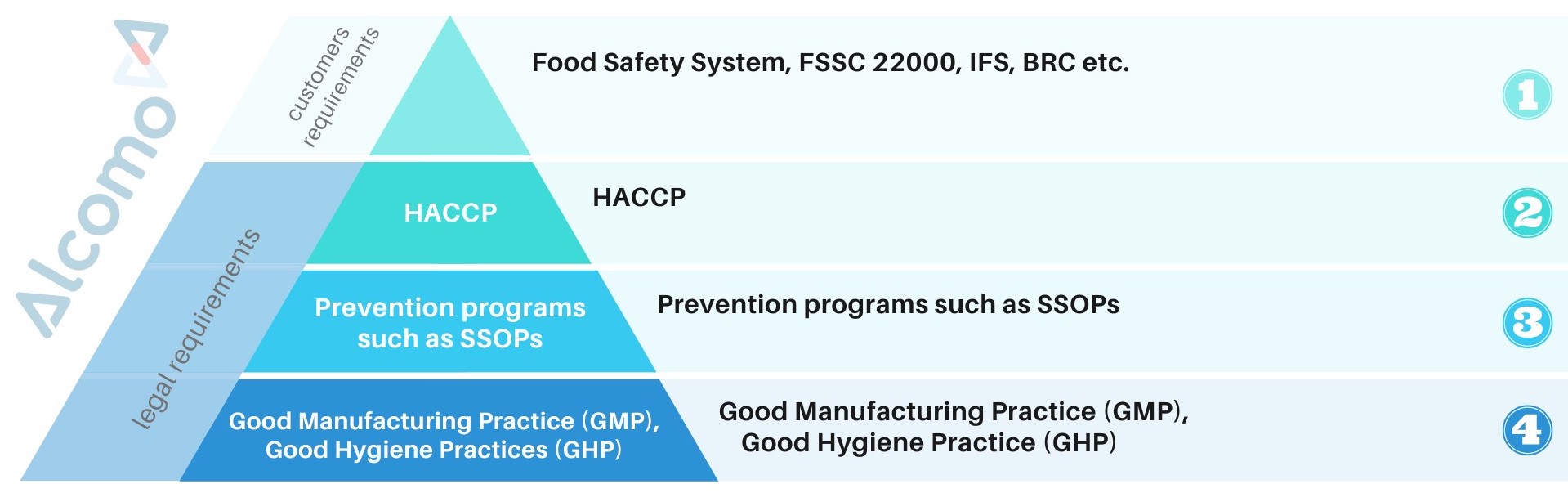

The food industry is one of the most heavily regulated sectors globally, and rightly so. Ensuring food safety is paramount, not just for protecting consumers but also for the reputation and compliance of food businesses. Hazard Analysis and Critical Control Points (HACCp) is a systematic preventive approach to food safety that addresses physical, chemical, and biological hazards from raw material production, procurement, and handling, to manufacturing, distribution, and consumption of the finished product. Despite its importance, one common challenge for companies adopting HACCP is the sheer volume of paperwork involved. However, with the advent of digital technology, HACCP paperwork can now be significantly simplified and streamlined.

Why Digital HACCP Systems are Game-Changers

The shift to digital HACCP systems not only reduces the physical burden of maintaining paper records but also brings numerous advantages:

- Instant Accessibility: Digital records are accessible from anywhere, anytime, allowing for real-time updates and reviews.

- Accuracy and Reduction of Human Error: Automated systems help in minimizing errors in data entry and record-keeping.

- Compliance and Auditing: Preparing for audits becomes much simpler with digital records. Traceability and documentation are immediately available, making audits more efficient.

- Cost and Time Efficiency: There are significant savings in terms of time and money when paper-based processes are digitized.

- Environmental Impact: By reducing paper usage, companies contribute positively to sustainability efforts.

Incorporating digital solutions into HACCP management can seem daunting, but the transition can be made seamless with the right approach.

Transitioning to Digital HACCP: A Step-by-Step Guide

The journey from paper-based to digital HACCP records involves several steps:

Assessment of Current Processes

Begin by reviewing your current HACCP procedures to understand where digitization can bring the most benefit:

- Identify key areas where manual record-keeping is the most time-consuming.

- Assess the complexity of your HACCP plan to decide on software capabilities required.

- Evaluate staff competence with digital tools to tailor training programs.

Choosing the Right Digital HACCP Software

The market offers a variety of HACCP software, each with its features:

- Features like mobile access, real-time data logging, automatic alerts, and reporting are essential.

- Ensure the software integrates well with existing systems like ERP, inventory, or quality management software.

- Look for user-friendliness, customization options, and scalability.

System Implementation

Implementation involves:

- Setup: Configuring the software to reflect your HACCP plan, including workflows, checklists, and monitoring requirements.

- Data Migration: Transfer existing records from paper to the digital system accurately.

- Training: Train all staff on the use of the new system, covering both the technical aspects and how it integrates with daily operations.

Ongoing Management

After implementation, ongoing management includes:

- Regular updates to ensure the software reflects changes in your HACCP plan or regulations.

- Maintenance of digital records to ensure compliance and audit readiness.

- Utilization of analytics provided by the system for continuous improvement.

💡 Note: The transition to digital HACCP should be seen as an investment in efficiency and compliance rather than just a cost.

Benefits of Going Digital Beyond Simplification

Apart from simplifying paperwork, going digital with HACCP offers:

- Enhanced Safety: Real-time monitoring and alerts can prevent food safety issues from escalating.

- Improved Traceability: Digital systems provide a clear path of product from farm to fork, crucial in case of recalls.

- Data-Driven Decision Making: With analytics, companies can make informed decisions to enhance food safety protocols.

Common Concerns and Solutions

Moving to digital HACCP systems often raises concerns which can be addressed:

- Security: Look for software with robust security features like encryption and user access controls.

- Reliability: Choose systems with cloud backup options to prevent data loss.

- Cost: Evaluate the long-term benefits and ROI; often, the initial investment pays off quickly with the efficiency gains.

The digital transformation of HACCP offers businesses in the food industry a new level of control and visibility over their food safety processes. It simplifies documentation, reduces errors, and speeds up response times in case of incidents. By choosing the right software and following a thoughtful implementation strategy, companies can not only comply with regulations but also enhance operational efficiency, customer trust, and ultimately, profitability.

What is the primary advantage of using digital HACCP?

+

The primary advantage is the significant reduction in time and effort for documentation and auditing processes, as well as increased accuracy and real-time monitoring capabilities.

Can digital HACCP systems handle different food safety regulations?

+

Yes, many digital HACCP systems are designed to be adaptable, allowing customization to meet various regulatory requirements across different regions.

How secure is the data in digital HACCP systems?

+

With features like encryption, user authentication, and regular security updates, digital HACCP systems provide robust security measures to protect sensitive data.

What if there is a power outage or system failure?

+

Most digital HACCP software offers cloud storage options, ensuring data can be accessed and stored safely even if there are local issues with power or hardware.

By embracing digital HACCP solutions, food businesses can streamline their safety and compliance processes, paving the way for a safer and more efficient future in food production and distribution.